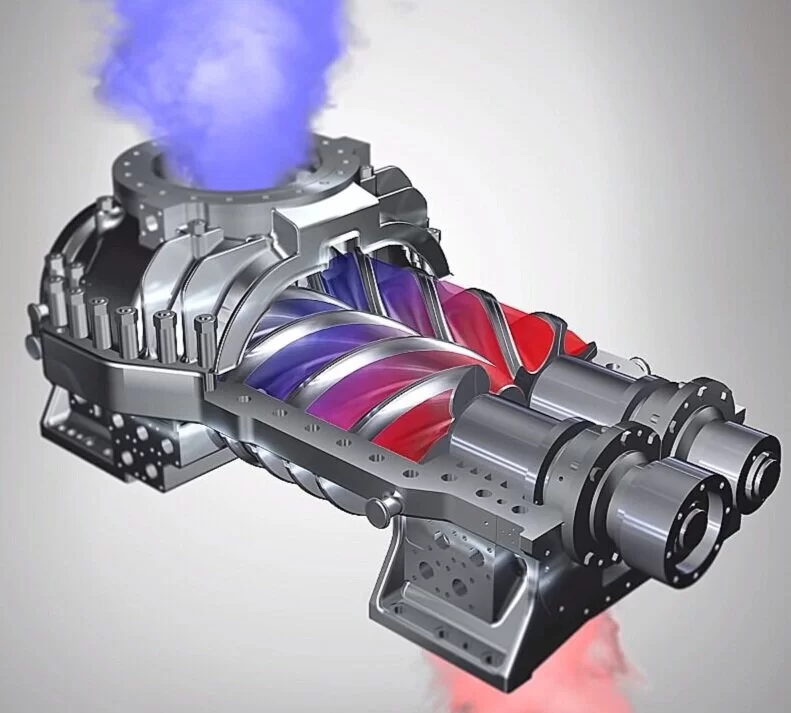

In the production lines of modern industry, the air compressor is an unknown but extremely important “energy carrier.” Among the many types of air compressors, double screw air compressor has become the first choice for enterprise users with the characteristics of efficiency, stability and energy saving. So why is it only the “double screw” that can stand out and become the “main force” in the field of compressed air? We’ll take you today to unveil its mystery. What is a double screw air compressor? What is a double screw air compressor? The core of a double-screw compressor is a pair of spiral rotors that are jointed with each other, called a positive rotor and a negative rotor. When they rotate at high speed, air is sucked into the cavity between the rotors and gradually compressed and expelled under the spiral propulsion, the whole process is continuous, stable and efficient.

Why are dual-screw air compressors so popular?1

Highly efficient and stable, without worrying about long-term operation, BENZAIR double screw air compressor does not enter complex components such as exhaust valves and pistons when working, and not only is the structure simple, but also operates smoothly. It can work 24 hours without interruption, and is widely used in various industries such as manufacturing, electronics, food, medical and other industries.2

Save energy and power, and operate at a lower cost compared with traditional piston air compressors, the energy efficiency ratio of dual screw air compressor is higher. It uses less energy and is more efficient over long periods of operation and is especially suitable for use in energy-cost sensitive plants.3

Lower noise, less vibration, and more friendly environment, BENZAIR screw compression structure operates smoothly, without violent impact or intermittent motion, so it has low noise and low vibration during operation, and is suitable for use next to production workshops or office areas with environmentally demanding conditions.4

Using maintenance is simpler there are no complicated transmission mechanisms, and there is no need to frequently replace parts. On a daily basis, only oil and filter changes are needed, and maintenance is very convenient.

What about other types of air compressors? Although there are also single-screw, piston and even centrifugal air pressure machines on the market, they have limitations:· The piston type: the structure is simple, but the vibration is large, the noise is high, and it is not suitable for continuous operation;· Single screw: complex structure and higher cost of maintenance and manufacturing;· centrifugal: suitable for very large volumes of traffic, but the startup threshold is high and the investment cost is high. BENZAIR Double-screw air compressors are at the “optimal balance” between efficiency, stability and cost, which is why they are widely used. As a professional manufacturer of air compressors, BENZAIR has been engaged in the field of compressed air for many years. A complete dual-screw air compressor product matrix has been built, covering several series such as standard type, permanent magnet variable frequency type, low pressure type, high temperature high humidity type, and other products, which broadly serve manufacturing enterprises around the world. We not only provide products, but also export overall compressed air solutions to help enterprises achieve green production and energy optimization.